Basic of Fire Extinguisher

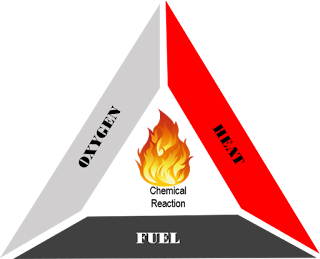

I would like to share my knowledge about basic of Fire Extinguisher. This Equipment is important for small protection avoid fire burning. Before i describe about Fire Extinguisher, i would like to share about Triangle of Fire. Why have the Fire, because : 1. Oxygen 2. Heat 3. Fuel We can getting Oxygen source from atmosphere, Normally in the athmosphere contain 21% Oxygen. So, Heat Source from Open Flames, Sparks, Hot Surfaces, The Sun and etc and then the last, Fuel source we can get from : Now, I would like to describe about Fire Extinguisher, which is before we buy a Fire Extinguisher, we have to know about Class and Type . Please see in the below about Fire Extinguisher Classification : Then you can determine which Fire Extinguisher will be assosiated in your place. Please see the picture in the below : I hope this article useful for you and everyone. If you need more detail, You can Download the Material via Google Drive without Free of Charge. Basic of Fire Extinguisher Modu...